Matters needing attention in operation of non-standard Automaton

Time:2019-11-01

Views:834

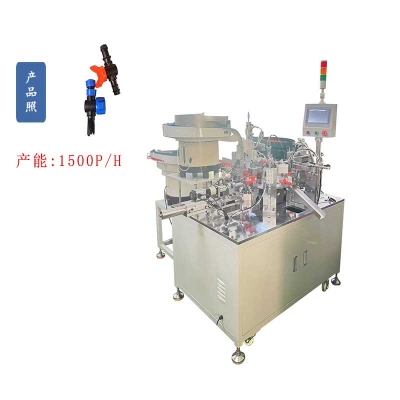

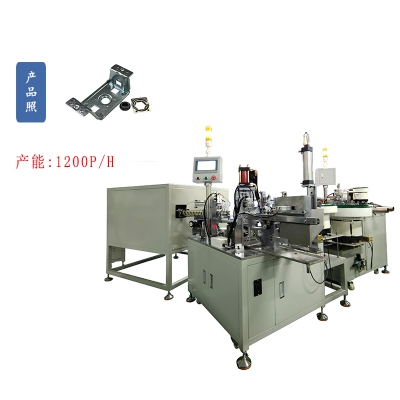

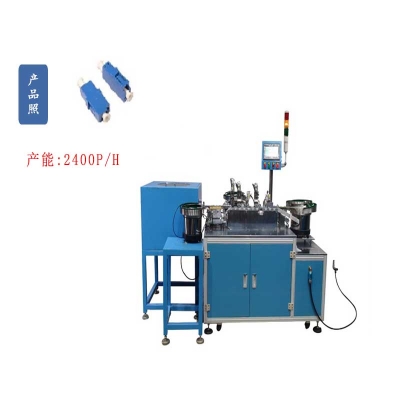

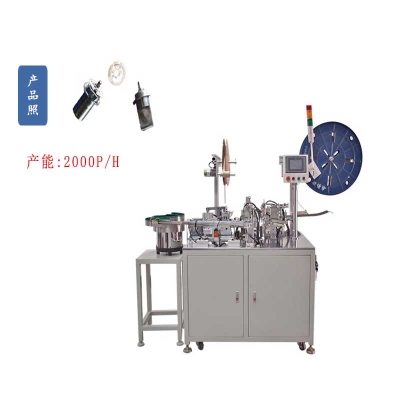

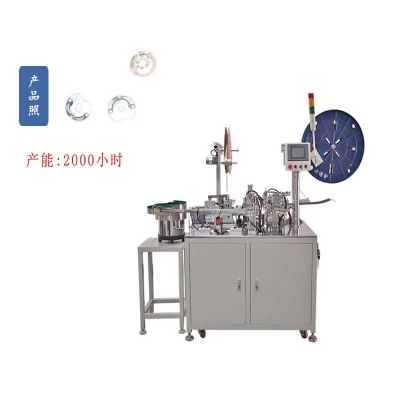

With the development of science and technology, the application of non-standard automation equipment is more and more extensive. How is it made? The manufacture of non-standard automatic equipment mainly includes two aspects: manufacture and debugging. 1. Equipment Making is the assembly of mechanical bodies and electrical components, the following points to note: Mechanical Installation: 1) after the screw is fixed with a marker pen mark; 2) need to refuel the nozzle mouth must be installed in the easy to operate place; 3) precision equipment must first adjust the level and then use anchor screw fixed; 4) the best place away from the power line cooling water. Electrical: 1) the more dangerous parts must be directly grounded from the primary distribution; 2) the high current through the place must be checked insulation; 3) Communication Lines and power lines must pay attention to anti-interference issues. 2. Equipment debugging is to debug the equipment according to the designed flow chart after the equipment is made. The main contents include: 1) to correct the original program according to the flow chart; 2) to correct the wrong communication line. Non-standard automatic equipment manufacturing is a comprehensive project, is a continuous work in the process of learning. Ericsson automation is a manufacturer of non-standard automation equipment. The main products are connector automatic assembly machine, potentiometer assembly machine, pin-row automatic machine, switch automatic assembly machine, pin-cut automatic machine, small household appliance assembly machine, etc. . non-standard automation equipment can solve the adverse effects caused by the loss of human resources, reduce personnel costs, improve production efficiency, thus bringing production benefits to enterprises.

.jpg) Wechat

Wechat

.jpg) Wechat

Wechat